The European construction sector is on the brink of a digital revolution, and at the forefront of this transformation is the ASHVIN project. ASHVIN is a novel initiative that is driving the digitalization of the European construction industry through innovative digital twin technologies. The ASHVIN Digital Building Twin solution can be deployed at three different phases of civil engineering projects: design, construction, and maintenance. Now, we will focus on discovering the ASHVIN toolkit tools dedicated to construction phase of the project to understand what the end-user can do with these tools, how these will support their work and where these tools have already been demonstrated.

Previously, we presented how the ASHVIN digital twin technologies can support the maintenance of infrastructure assets. Discover more about it here!

What is ASHVIN?

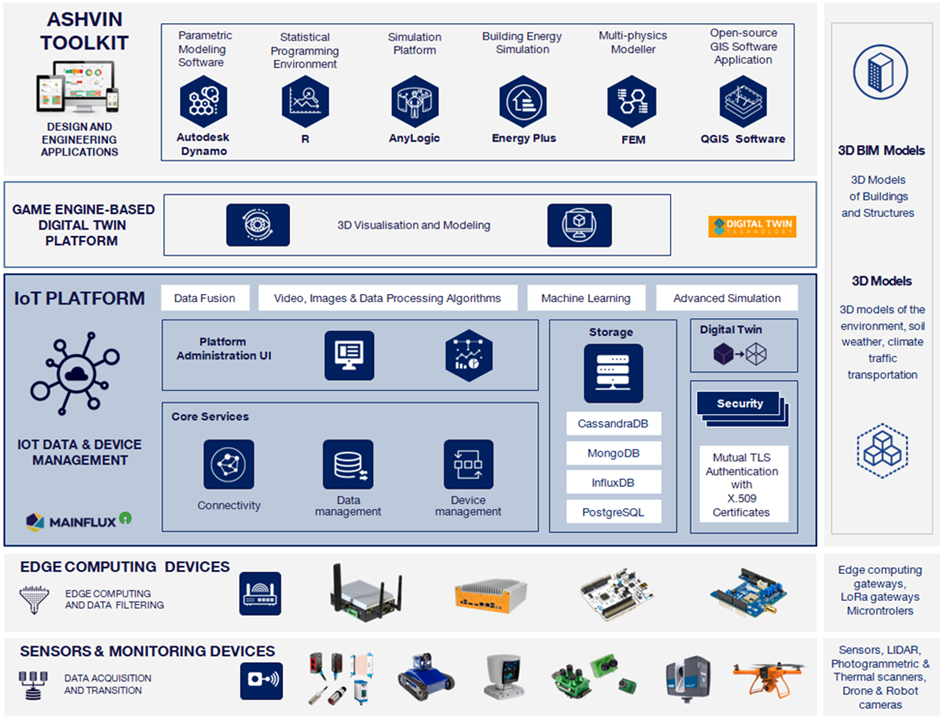

The ASHVIN project, funded by the European Union’s Horizon 2020 program, brings together a consortium of experts from various fields, including construction, engineering, and information technology. Its primary objective is to develop a novel system based on digital twin technologies aiming to boost the construction industry’s project management. This system includes a toolkit of 10 smart building applications analysing data that is collected with (a) a variety of sensors and sensing devices installed at the construction sites and infrastructure assets, and with (b) a digital twin platform enabling to visualise the collected and analsysed data. The objective of the ASHVIN system is to support construction project managers and workers, and to boost productivity and safety of construction sites and infrastructure asset management.

Digital Twins: Transforming Construction

Digital twins are virtual replicas of physical assets or systems. In the context of construction, a digital twin represents a building or infrastructure project in a digital form. ASHVIN takes this concept to the next level by creating adaptive digital twins that continuously update and adapt to real-world conditions.

Here’s how the project is making a difference:

Real-time Monitoring: Once construction begins, ASHVIN’s digital twins continuously monitor the project’s progress and performance. Sensors and data analytics are used to gather information about various aspects, such as productivity, resource efficiency, and worker safety.

Predictive Analytics: By analyzing real-time data from the digital twin, ASHVIN can predict potential issues or bottlenecks before they become critical problems. This proactive approach helps prevent delays and cost overruns.

Collaboration and Communication: ASHVIN promotes collaboration among all stakeholders involved in a construction project. The digital twin serves as a central platform where architects, contractors, subcontractors, and project managers can share information, updates, and insights in real time.

Sustainability and Resilience: The project strongly emphasises sustainability and resilience. The adaptive digital twins allow for dynamic adjustments to improve energy efficiency and to enhance the resilience of buildings and infrastructure to various external factors.

Tools for Construction Phase

ASHVIN team has developed four tools dedicated to the construction projects, and they all have been deployed at least at one demonstration site.

Implementation across 3 demonstration sites

The project has piloted the developed digital twin tools for construction at three demonstration sites, in three different countries:

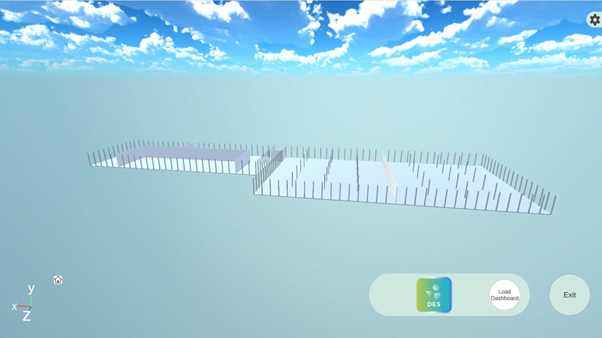

Firstly, Logistic hall construction in Germany (Demo Site #4) was managed by Technthe ical University of Berlin (TUB), which is also the scientific coordinator of the project. The goal of this demo site was to support construction management through a digital twin, enabling continuous work processes through timely delivery of prefabricated components and efficient equipment usage. Time-lapse images were collected to show the updated status of ongoing works. The challenge of this site was to achieve a continuous data stream for building a digital twin. Two ASHVIN tools, 4DV-C and DES were deployed at this site.

Simulation with the DES tool of the demo site #4

Secondly, Kineum office Building in Sweden (Demo site #5) is managed by the ASHVIN end-user partner, NCC . At this site, the goal is to create a dynamic digital twin with tailor made support feeding back to the site management during construction works, health and safety improvements on site using the dynamic digital twin. The main challenge has been the use of the BIM model, developed in the design phase, in the production phase and to feed data into the model that will provide support to the site management as well as information and knowledge to the construction workers. Four tools, SMT, CMT, 4DV-C and DES, were piloted at this site.

Also, check out our video presenting the demo site #5!

Thirdly, the Office Building in Spain (Demo site #6) was led by Polytechnic University of Catalonia (UPC). This site focused on concrete buildings during construction. For this demo site, kinematic data were collected to track crane movements. The ASHVIN platform enables a centralised dashboard to be used by construction managers. This site demonstrated the deployment of three ASHVIN tools targeting the construction phase: 4DV-C, CMT and DES.

Demo Site #6 Visualisation with the 4DV-C Tool on the Digital Twin Platform (image above).

The demo site #6 visit for data collection (image below).

Impact for European construction of tomorrow

The collaborative innovation and research efforts of the ASHVIN consortium aim at shaping the digitalized European construction sector of tomorrow. The ambition is that by using the ASHVIN tools for construction, the construction projects meet:

- Better scheduling forecasts

- Improved allocation of resources

- Reduced number of accidents

- Reduction of cost by 20%

These are key performance indicators that the ASHVIN team continues to assess as a last steps of the demonstration site research, and we will continue communicating about these results during the remaining project months.

Moreover, at the end of the ASHVIN project, in the end of March 2024, all the developed tools meet the technology readiness level 6, meaning that they have been demonstrated in real-life environments.

To learn more, consult our following related results:

Scientific publications related to ASHVIN’s research

Conference publication: Platology: A Digital Twin Ontology Suite for the Complete Lifecycle of Infrastructure (read more)

Conference publication: Virtual construction with digital twins – The key for leanly planned complex construction systems (read more)

Conference publication: A survey for image based methods in construction: from images to digital twins (read more)

Conference publication: Real-Time Activity Duration Extraction of Crane Works for Data-Driven Discrete Event Simulation (read more)

Scientific article published in a journal: Detecting anomalies and de-noising monitoring data from sensors: A smart data approach (read more)

Conference publication: Combined Digital Twin and Location-Based Management System (read more)

Conference publication: Discrete Event Simulation Tool for Productive, Resource-Efficient, and Safe Construction Management (read more)

ASHVIN Deliverables

D1.4 Digital Twin Interoperability in the Construction Industry (download)

D1.5 Safety and Privacy for Digital Twins in the Construction Industry (download)

D3.1 Visual Analysis for Real Sensing (download)

D3.3 Data Fusion Methods and Digital Twin-based IoT Data Processing Pipelines (download)

D4.1 A Set Of KPIs To Plan And Monitor Productive, Resource Efficient, And Safe Construction Sites (Download)

D4.2 Discrete Event Simulation Formalism for Productive, Resource Efficient, and Safe Construction Planning (Download)

D4.3 Digital Twin supported lean project planning, control and risk management (Download)

D4.4 Risk Management (Download)

D4.5 Virtual Commissioning Model (download)

D4.6 Visualizing and Dashboarding Construction Activities Based on Digital Twin Data (download)

Webinar

Watch our first technical webinar dedicated to the ASHVIN’s digital twin platform for construction projects.

Podcast – ASHVIN Innovation Stories on Construction

Our several podcast episodes offer insights into our researchers’ innovation in construction:

Digital twins for construction processes by Manuel Jungmann from Technical University of Berlin (listen now)

A new process model to control the construction phase by Rogier Jongeling from Plan B (listen now)