The ASHVIN solution using digital twin technologies will boost the European construction industry making it more performant, more sustainable, and safer. This system, combining a set of digital twin applications connected to an open access IoT platform, is piloted in 10 real-world demonstration sites, and the demonstration site #5 “Kineum office building” in Sweden is now running with the focus on supporting the construction.

What is the demo site #5?

The Kineum demo site is a high-rise building located in the city of Gothenburg, Sweden. This construction project started in 2019 and ended in summer of 2022. The ASHVIN Project partner NCC ( ↗️ ) is responsible for building this 27- story office building with integrated hotel and spa and a total height of 110 meters. This building project aim for BREEAM certificate Excellent in the office part and Very Good in the hotel part.

What is the desired impact?

For this complex project, the ASHVIN demo focuses on developing a dynamic digital twin with tailor made support feeding back to the site management. This provides an opportunity to demonstrate possibilities to integrate engineering data and the construction planning and processes, building on historical and synthetic data for modern analyses in the digital twin. The established 4D model allows planning and monitoring of resource use, productivity, and safety.

NCCs specific objective is to explore new ways of collecting data and translating this data into information and knowledge. As a lot of building data is currently collected manually and stored on paper or in pdf-format, and there is a huge productivity potential if the data could be collected automatically. Furthermore, frequent collection of data can ease the identification of possible errors, which will decrease cost of re-work.

How ASHVIN runs on the demo site?

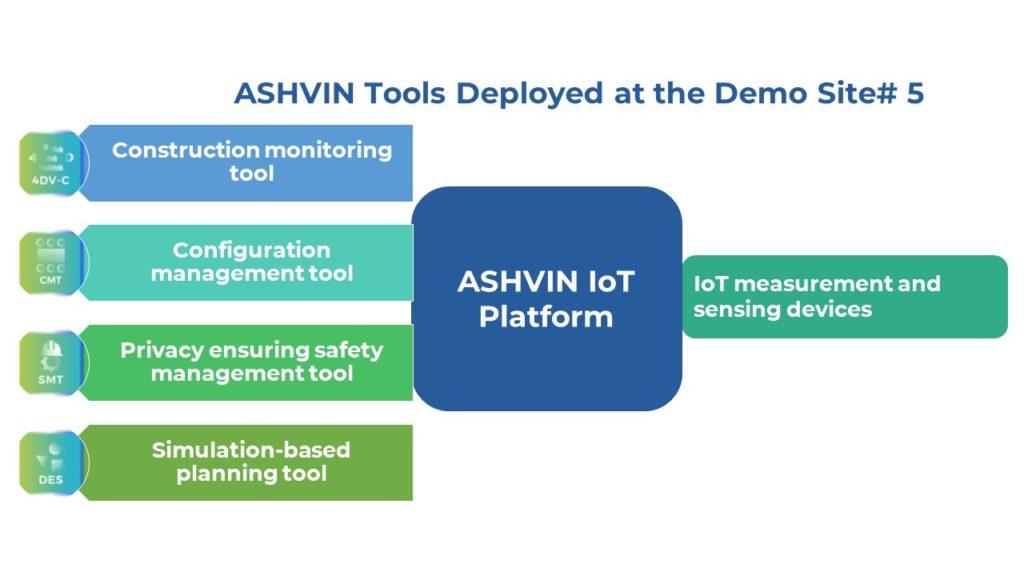

The ASHVIN platform is deployed together with a set of sensing and imaging sensors gathering data from the construction site. Kineum demo site will validate following ASHVIN tools:

- 4DV-C is construction monitoring tool with productivity and safety KPI decision making dashboard.

- CMT is a configuration management tool to track as-designed and as-built, as well as, to allow for seamless commissioning.

- SMT is privacy ensuring safety management, simulation, and training tool.

- DES is simulation-based real-time construction site and logistics planning tool

These three tools are part of the ASHVIN digital twin toolbox (↗️) counting ten different tools. These innovative applications are built upon the ASHVIN digital twin platform and are linked to digital twin data.

In addition to the tools, the 4D model is analyzed in conjunction with data from the site collected by cameras and sensors. To scan some parts of the demonstration building and to capture images and video streams for later image recognition analysis, NCC has deployed their SPOT robot (purchase not funded by the EC) that is a quadruped robot that can climb stairs and traverse rough terrain, making it suitable for construction sites. The ASHVIN system used this data acquired SPOT in the development of a dynamic digital twin of the Kineum demonstrator and to effectively track the progress of the project and the quality of the work.

What is the status?

The data measurements are now finished. The data was gathered from February 2021 to May 2022 measuring notably temperature, RH, dust, noise, evacuation alarm and activity at the construction site. Also, a Laser Scan was deployed.

Now, the three ASHVIN tools under implementation, and these are linked with the digital twin data.

What challenges have been faced?

The construction site is very small and therefore, health and safety are the priorities. The limited in size of the building site put logistic constraints, and the construction site environment and the surrounding areas needed to be considered throughout the construction process.

What are the next steps?

The research of the gathered data continues with the created digital twin and the connected ASHVIN tools. The goal is to support the construction site manager in monitoring:

- Temperature and humidity in the building

- Workers progress at the site

- Waste management

- Space use with heath maps.

- In depth investigations of Accidents and incidents

See the video (↗️) of the SPOT robot working at the demo site 5 !

For more information please visit our Digital Toolkit Page (↗️), download our official deliverable and connect with us through our LinkedIn or Twitter communities!