The ASHVIN solution uses digital twin technologies to boost construction site management, making it more efficient while reducing costs, more productive while using all gathered data and safer while anticipating risks. ASHVIN offers an IoT-driven digital twin platform connected to the ASHVIN toolkit composed of 10 smart building tools. The solution is validated at 10 European demonstration sites covering different building types, from bridges to buildings and stadium roof structures. ASHVIN Demonstration #6 Office Buildings, located in Barcelona, Spain, is one of the 10 demonstration sites of the project.

What is demo site # 6?

This demonstration site is an office building located in Barcelona city. The construction is part of the project 22@, also known as 22@Barcelona and “Innovation district” (“Districte de la innovació”). Construction started in January 2022, and ASHVIN collected data between June 2021 and December 2021. Access to the site was provided by Dragados (Construction company) together with BCA (Architectural designers), BIS (Structural site managers) and FREO (the building owner).

Barcelona’s innovation district

The 22@Barcelona project changes the urban, social and functional structure of the central areas. It contributes to the transformation of Barcelona from the City of Industrial Civilization into the City of Knowledge Civilization. It aims to convert the industrial area of Poblenou into the city’s technological and innovation district, as well as to increase leisure and residential spaces.

Several recent construction sites at 22@ are under the management of BIS, a Barcelona-based structural engineering office. BIS manages design and supervision while constructing highly technical structures in the building sector in Spain and other countries. The company agreed to collaborate with ASHVIN by providing access to this demonstration site.

What is the desired impact?

At this site, ASHVIN’s goal is to facilitate and support the construction process from the perspective of materials, structures, geometry, processes, quality and safety.

How does ASHVIN run on the demo site?

This case study is about concrete buildings during construction. BIS structures, a Barcelona-based structural engineering office, together with many other stakeholders, agreed upon collaborating with ASHVIN by facilitating access to MILE – a Business Campus project construction site. MILE is an office building project of 38.093m2, divided into three complexes: MILE Badajoz, MILE Llull, and MILE Ávila. The access was provided for the specific module of MILE-Ávila, a cast-in-place reinforced concrete building of long-spanned post-tensioned slabs consisting of eight levels and a total area of 16.524m2.

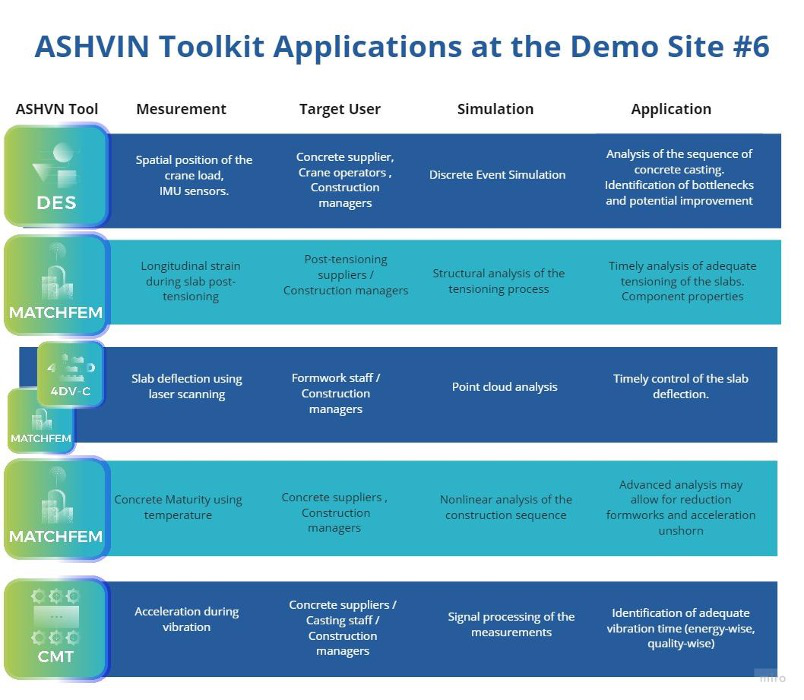

Five tools of the ASHVIN toolkit are deployed with the data collected from this site. The collected data covers the following construction aspects:

- The temperature of fresh concrete (strength of materials and components properties),

- The vibration of concrete during the casting of columns (Accelerometers),

- Slabs deformation point cloud (TLS) 6 measures,

- Strain gauges (post-tensioning of slabs).

- Tracking of crane hook (GPS, accelerometers, barometer) 1 week of measures.

See our short video about the demo site from LIDAR to digital twins.

The following ASHVIN tools are implemented to support the office building construction process in Spain:

- 4DV-C is a construction monitoring tool with a productivity and safety KPI decision-making dashboard;

- 4DV-D is a construction site simulator for early design phases with a 4D visualizer

- MatchFem is a multi-physics model matching tool for the status assessment of bridges and buildings

- CMT is a configuration management tool to track as-designed and as-built and to allow for seamless commissioning

- DES is a simulation-based real-time construction site and logistics planning tool

- MatchFEM is an enabler that allows connection between BIM-FEM and IoT.

For more information about the tools and find our tutorials on our ASHVIN toolkit page.

What is the status?

The Data collection phase is finished, and the measurements are implemented in the IoT-driven Digital Twin ASHVIN platform and the five connected ASHVIN tools. The construction finished in 2022, and the building is presently being populated and in service.

What challenges have been faced?

This demonstrator provides an ideal testbed to overcome some frequent construction challenges. Firstly, the construction site is within an urban area where stringent conditions related to time and space apply. Space is limited, and traffic cuts are strictly limited. The concrete casting is continuous, representing a critical aspect of the use of space around the site. Secondly, the site analysis of machinery and space allocation during sequential construction can be studied using a digital twin approach.

What are the next steps?

Implementation of automatic pipelines of information is at the advanced stages. The ASHVIN platform enables a centralised dashboard to be used by construction managers, and now they can visualise in an aggregated manner different sources of information on a selected moment. A timely use of this information opens manifold possibilities for a timely analysis of the construction process. During this process, managers can elicit data gathering from many perspectives according to the construction site singularities. As a result, the specific monitoring of one site becomes tailor-made with the potential to improve the process at the right time.

Demo 6 in the ASHVIN platform Dashboard

Moreover, specific pipelines of information are being embedded into the platform. As a result, measurements, geometries and tools are blended; each pipeline represents an application of interest for varied stakeholders during construction, as explained in the image below.

Stay tuned for more ASHVIN results, and connect with us through our LinkedIn or Twitter communities!