The ASHVIN project is nearing its end, and now it is time to showcase the major technical results of this 3.5-year research project! Since 2020, the ASHVIN team has developed a digital solution for the construction industry, deploying digital twin technologies to boost the productivity, efficiency, and safety of construction and maintenance projects.

The ASHVIN system deploys digital twin technologies for construction projects

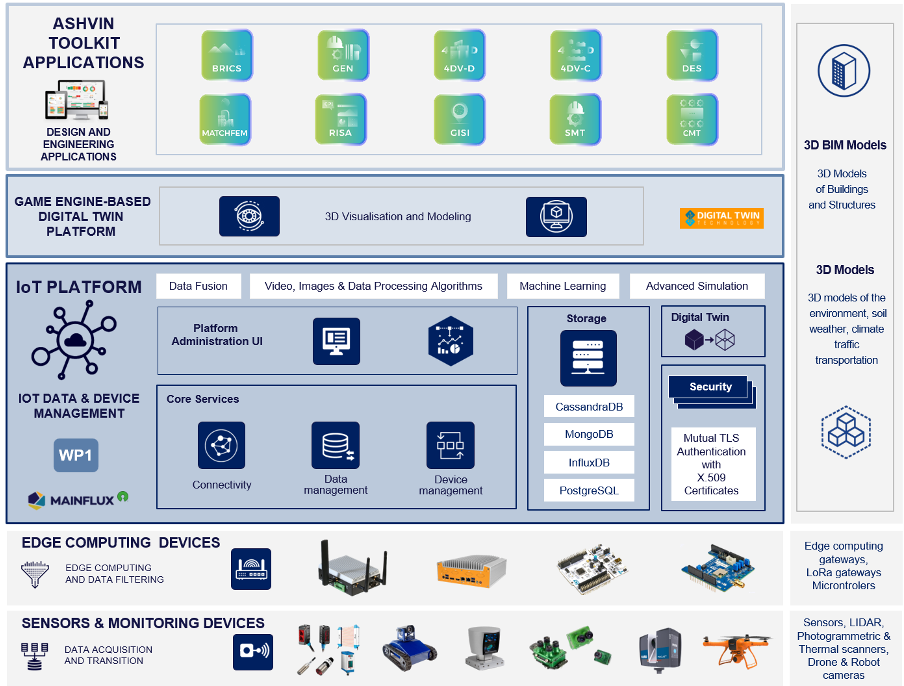

The digital ASHVIN system includes several technical layers that enable the end-users to collect data from construction sites or infrastructure asset sites, analyse and monitor the collected data, and visualise it through a dedicated digital twin platform. This enables notably better and more informed decision-making, risk anticipation, and damage detection across construction and maintenance projects.

The figure below shows that the ASHVIN platform integrates sensor devices and edge computing instances to collect data. This data is fed to the ASHVIN system via an Internet of Things platform (IoT) (created and managed by Mainflux), allowing connectivity, data management and sensor/edge computing device management. This platform is integrated with the game engine-based digital twin platform (developed by Digital Twin Technology) that allows 3D visualisation. In addition, the ASHVIN toolkit, composed of 10 digital smart building tools, runs on the Digital Twin platform, enabling it to monitor and assess different aspects of the project based on its needs.

Focus on the IoT platform - running on the backend of the ASHVIN system

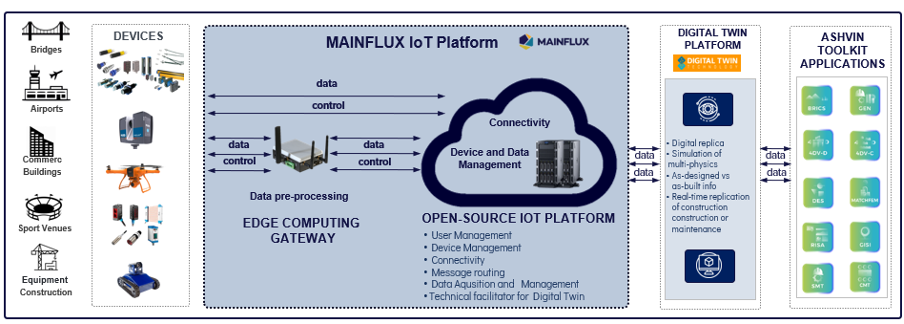

The ASHVIN digital twin system relies on data gathering from multiple sources. This necessitates enabling them to access gathered data, preferably in a standardised format from a centralised repository, whether gathered in the past or in real time.

The Mainflux IoT Platform serves as the backbone of the ASHVIN technology stack and the technical facilitator for the entire system, providing all essential functionalities, including:

- Data management: real-time messaging, streaming, aggregation, processing, and secure storage of IoT data

- Device Management: registration, monitoring, discovery, provisioning, control and management of IoT devices, providing a comprehensive overview of device health and activity.

- User Authentication and Authorization: ensures security by implementing robust authentication and authorisation mechanisms to control access to devices and data

- Multi-Tenancy: serving multiple users and applications concurrently, keeping their data and workflows separate and secure

- User Interface: interactive user interfaces, visualizing real-time sensor data, and managing devices and users.

The Mainflux IoT platform fosters the overall technology of the ASHIN system

Particular added values that the Mainflux platform provides to the ASHVIN System come from its two important features:

Mainflux, written in Go (Golang), brings several advantages due to the language’s design and capabilities. Golang is known for its simplicity, efficiency, and strong support for concurrency (multiple computations are happening at the same time). This means Mainflux can handle multiple device communications and data processing tasks simultaneously without compromising performance. The compiled nature of Go results in fast execution and deployment, which is crucial for time-sensitive operations in the IoT domain and the dynamic needs of the construction industry and beyond.

In addition, the Mainflux IoT Platform’s small footprint is particularly beneficial for the construction industry, which often involves operations in remote or temporary locations with limited infrastructure. A small footprint means the platform can run on less powerful hardware or in constrained environments, reducing setup and operational costs. Despite its minimal resource requirements, Mainflux does not sacrifice scalability or robustness. It can manage a large number of devices and high volumes of data thanks to its efficient design and the use of technologies like Docker and Kubernetes for containerisation and orchestration. This scalability ensures that as construction projects grow or as more IoT devices are added, Mainflux can seamlessly accommodate this expansion, maintaining its performance and reliability.

These two characteristics of Mainflux combine to offer a potent solution for IoT applications, especially in sectors like construction, where flexibility, efficiency, and reliability are paramount.

Mainflux Basic Entities presented in User Interface

The IoT platform’s user interface has been finetuned according to feedback gathered from end-users. This interface, axed around different basic entities, is proven to be user-friendly:

- Organisations and Groups: These are used to organise and manage users, devices, and other entities within the platform. Groups allow for easier access control and permissions management, enabling administrators to efficiently assign roles and rights to multiple users or devices simultaneously rather than individually. This feature simplifies the administration of large-scale IoT deployments by grouping entities that share common area, space, and characteristics or need similar access levels.

- Things: In Mainflux, ‘things’ represent devices or applications. Each ‘thing’ is identified by a unique key used for secure communication.

- Channels: These are the communication links through which ‘things’ publish and subscribe to data. They dictate the flow of information within the platform.

- Users: These entities manage ‘things’ and ‘channels’. They have the capability to create, configure, and control access to IoT devices and the data they generate.

- Messages are structured data packets that ‘things’ send and receive through channels. They carry information that the platform processes, stores, or analyses.

“In essence, the Ashvin project has contributed to the evolution of the Mainflux IoT platform by enhancing its technological framework and expanding its application range, incorporating sophisticated sensing, video, and image monitoring technologies and integrating with a game-engine-based Digital Twin platform. Additionally, the user-friendly GUI and toolset are specifically engineered to meet the demands of the construction industry”,

Sasa Klopanovic, Managing Director, Mainflux Tweet