The ASHVIN solution uses digital twin technologies to boost construction site management, making it more efficient while reducing costs, increasing productivity and safety while anticipating risks. ASHVIN offers an IoT-driven digital twin platform connected to the ASHVIN toolkit composed of 10 smart building tools. The solution is validated at 10 European demonstration sites covering different building types, from bridges to buildings and stadium roof structures.

ASHVIN Demonstration #10, Quay wall located in Rotterdam, Netherlands, is one of the 10 demonstration sites of the project. This pilot is designed to assess how digital twins can support the maintenance of such an infrastructure asset.

What is demo site #10?

The ASHVIN Demo Site #10 was extensively instrumented during constructions including the use of fibre optic sensors. These sensors measure, for example, displacement of the retaining wall, loads on the foundation piles and loads on the fenders. These measurements give an indication of how the quay wall responds to changes in the external environment, such as loading from ships or changes in seabed level, along with time-related changes such as material degradation.

Generally, advanced computer models have been used to assess quay wall safety. These models allow the asset owners to make decisions regarding the remaining lifetime and adaptability of a quay wall. However, uncertainties regarding soil properties and soil behaviour means it is necessary to validate the results of the model. This can be done using the ASHVIN Digital Twin solution.

What is the desired impact?

The ASHVIN team’s research aims to reduce these soil properties and model uncertainties using a combination of fieldwork, laboratory tests, numerical analyses, and life-cycle assessments. By taking this holistic approach, the work will significantly advance the scientific state of the art by developing and validating advanced numerical and probabilistic methods for calculating the safety of quay walls.

Ultimately, the ASHVIN system supports the operation and future construction works, e.g. how much additional load can be put on the quay wall or how much deeper they can dredge in front of the wall to allow for larger ships.

How does ASHVIN run on the demo site?

All the data from the different quay wall components, including piles, retaining walls, and monitoring wells, have been analysed. While doing this, we also developed a digital twin of the quay wall using finite element modeling. By combining the measurement data and the numerical model, we were able to refine the input parameters for the quay wall and validate the quay wall results. This analysis was further helped by a data fusion collaboration between two ASHVIN research partners, InGEO and CERTH, where external data sources were combined with local measurements to come up with a good interpretation of the water levels in front of and behind the quay wall.

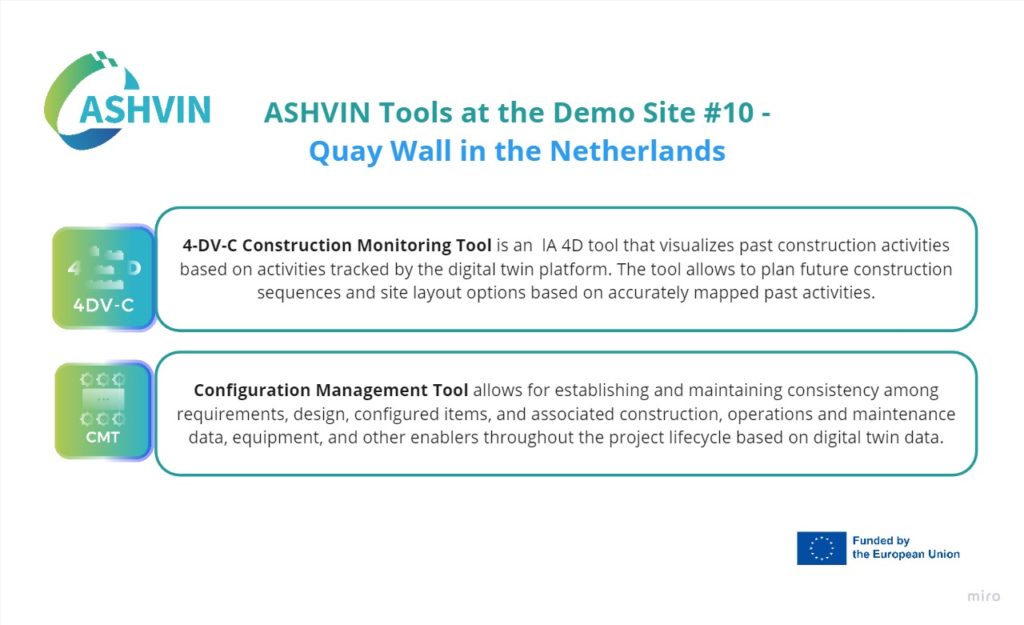

As part of our digital twin development, we also developed a BIM representation of a section of the quay wall. To assist with these processes, we have been implementing CMT and 4DV-C tools:

What is the status?

The digital twin of Demo Case #10 has been developed and incorporated into the ASHVIN platform. The team is now implementing the approach to a number of urban retaining walls located across the globe.

What challenges have been faced?

Quays walls represent a significant economic investment. Prolonging the life or repurposing allows for significant economic and environmental savings to be achieved.

A predictive twin of the quay wall allows engineers to combine monitoring data and numerical models, gaining new insights into the physical mechanisms governing quay wall reliability. Calibrated models allow them to perform stress-tests and field tests, such as loading the back of the wall or dredging in front of the wall, to confirm the model’s real-time performance. Probabilistic life-cycle models also help them to compare the complete financial and environmental costs of such systems.

The most challenging aspect of conducting this design and engineering research has been modeling the structural response of the quay wall over its lifetime using a finite element model while incorporating monitoring data into a reliability model. Ensuring the stability and quality of a long-term monitoring programme is also vital to the success of a digital twin.

What are the next steps?

Digital twin development has given us insights into long-term effects on the quay wall, such as the influence of changing loads, temperature and water level variation. Using the data collected, we are analysing how these effects might influence the quay wall’s reliability in the distant future.

Stay tuned for more ASHVIN results, and connect with us through our LinkedIn or Twitter communities!