ASHVIN WP4 “Control and real-time simulation of construction” develops applications for better managing and controlling construction site activities using digital twin data. Deliverable 4.2 entitled “Discrete event simulation formalism for productive, resource efficient, and safe construction planning” was published in September 2022 along with 11 other technical deliverables defining the ASHVIN system. It is related to task 4.2 “Real-time discrete event simulation” led by TUB.

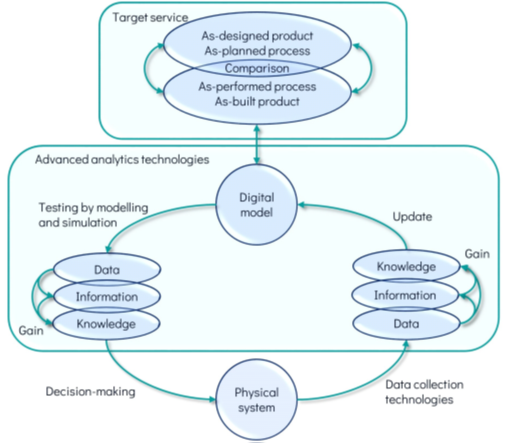

This deliverable explains how the developed approach can be used to apply data-driven, real-time discrete event simulation during construction execution to manage the ongoing production processes. In close alignment to three demonstration cases of the ASHVIN project, frequently used work process patterns were determined. Derived from the construction work process patterns, discrete event system specification formalisms were developed. During the production process, raw data were gathered in real-time. These collected data were analysed to gain information and knowledge by artificial intelligence about the as-built product and the as-performed process. In particular, activity durations are determined, which are used within stochastic productivity modelling to determine suitable probability density functions. These probability density functions are input for the activity durations in the modelled discrete event simulation.

The developed discrete event simulation mechanisms can account for supply-chain logistical, resource dependent, and spatial characteristics of the respective construction site. Additionally, disturbances by weather conditions or during material deliveries can be considered. After successful calibration of the model, different construction options are compared by the data-driven discrete event simulation in consideration of Lean Construction principles according to automatically calculated productivity, resource efficiency, and safety-related key performance indicators.

Thus, the improvement of future supply-chain logistics, resource allocations, and site layouts can be enabled based on current representations of construction sites as digital twins.

Download the entire report in Open Access via Zenodo.

For more information, visit our Digital Toolkit Page, and connect with us through our LinkedIn or Twitter communities!