ASHVIN project aims at the digitalization of the construction industry to increase productivity, resource efficiency, and safety. Towards this goal, digital twin technology is only one means to an end. Therefore, the core of all ASHVIN development aims at introducing two major process innovations enabled by the possibility to closely match as-build information with as-designed information throughout the product development lifecycle that is made possible by digital twin technology.

ASHVIN develops digital processes that will allow for the seamless integration of all stakeholders within and across the design / engineering, construction, and maintenance of buildings and infrastructure. Vertical integration will be achieved by possibilities for back- and forward information and knowledge flow through all stages of the product development process. ASHVIN establishes design and engineering processes that can leverage experiences and lessons learned from past projects (evidence-based design). These processes can project the effects of design choices on the productivity, resource efficiency, and safety during early design stages (constructability analysis through generative design). By the core nature of the digital twin solutions a direct match between as-designed and as-build information will be achieved to ensure seamless knowledge and information integration from design /engineering phases to construction and further on to maintenance stages. ASHVIN develops corresponding process templates and recommendations as well as the required interoperability solutions and standards.

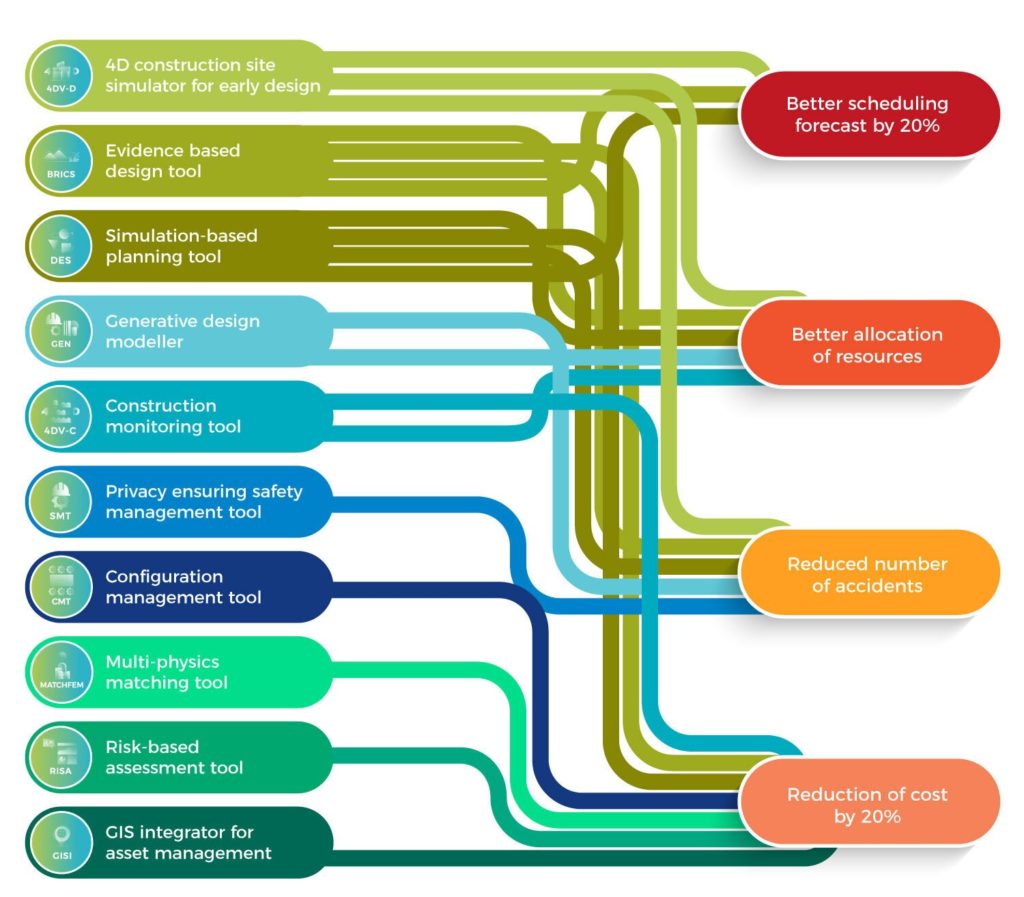

To achieve horizontal integration through all project phases, ASHVIN develops a set of clear impact indicators (Key Performance Indicators) that will allow steering the product development process in all phases jointly towards common goals as can be seen in Figure 1. In the project Key performance indicators (KPI) are performance aspects which are used for evaluation productivity, resource efficiency and safety of construction process. While the Performance indicators (PI) are a number of related and quantifiable and measurable parameters that constitute a KPI.

Figure 1: Illustration for the relation between ASHVIN tools and expected project outcomes monitored by using (K)PIs

Based on these KPIs (Productivity, Resource Efficiency, Safe construction work, Cost) advanced dashboarding and visualisation methods will be developed that will allow presenting digital twin information to all important stakeholders and decision makers at every stage in the design process. Together, KPIs, dashboards, and visualizations will allow for true collaborative decision making that is based upon facts established by an accurate representation of the real-world conditions by digital twins. A specific focus for horizontal integration is on the construction phase. For the construction phase, ASHVIN designs lean planning and control processes that will allow to integrate all parties that need to work together on a construction site to engage in collaborative decision-making processes. The lean processes will allow using digital twin data to clearly map value streams (in terms of productivity, resource efficiency, and safety), communicate these value streams among all parties involved during construction, and, in turn, allow for establishing information and material flows that truly rely on a pull system minimizing waste, idle resources, and circumventing unsafe construction conditions.

For more information please visit our Digital Toolkit Page, download our official deliverable and connect with us through our LinkedIn or our Twitter communities!